This is where most Kickstarter tasks fall short since business people undervalue the money and time necessary to go beyond this section and do the Design for Producing (DFM) optimizations, put together the molds, setup production, and acquire items collectively.

Instructional applications: Prototype boards tend to be used in instructional options to teach learners about circuit design and electronics.

It is usually doable to produce a buzz with the appearance of prototypes, beginning demo uses, and early marketing campaigns. With the continuous progress in 3D/CGI rendering software, you don’t really need to make a prototype so that you could start out your advertising and marketing campaigns.

A lot more Hamburger icon An icon used to stand for a menu which can be toggled by interacting using this type of icon.

Clay and foam are two of The best supplies for producing early seems-like prototypes. Naturally these components received’t produce a functional prototype but These are exceptional for experimenting With all the kind of your merchandise.

Distinct technological demands increase the chances of a swift and seamless development system. And that includes building a prototype that won’t need to have significant or high priced modifications.

We provide organizations, companies, and entrepreneurs in lots of industries. It does not matter the dimensions or software, we guarantee every purchaser is glad once they associate with us for their plastic job.

Also referred to as EP or engineering prototype, Here is the phase where by the looks-like and functions-like prototypes are combined into 1 useful prototype with the overall look closely resembling the final item. electronic prototype It is additionally the prototype typically useful for demo needs and crowdfunding strategies such as Kickstarter. The custom made-designed PCB plus the tailor made-designed enclosure are integrated. The housing will go back and forth involving the commercial designer, who will finetune the shape and aesthetics, as well as mechanical engineer will integrate the electronics in the plastic shell while making sure the item adheres to engineering criteria.

On the other hand, building test samples electronic prototype companies minimizes the development time on a substantial scale: it reveals and can help reduce essentially the most critical challenges at early phases.

ABS. This trustworthy thermoplastic is widely Utilized in industries like customer electronics. It delivers general-intent effectiveness for elements like electronics enclosures and handheld equipment, and can be relatively economical.

Namethis industry is needed Companythis industry is required E-mailincorrect e-mailthis industry is needed Phone number (optional) Convey to us more herethis industry is necessary

Occasionally, reworking is usually Similarly or even more laborious and high-priced than repeating prior techniques Should the defects are hard to correct or have to have replacement elements. This electronic prototype construction can even more add on the Restoration-system timeline.

If we are unsuccessful to reduce all the failings or these tries bring about new difficulties, the prototype remains viewed as a Beta and the procedure repeats. Once the staff efficiently eradicates all the issues as well as the device performs as supposed (performing every one of the features), We've a pre-creation prototype. It is this iteration that goes for mass creation. At this stage, the prototyping course of action is around.

This tutorial discusses prototyping a normal client electronic merchandise with electronics inside and an outer plastic enclosure. This kind of products can be for dwelling automation, IoT products, pet merchandise, or other “intelligent” equipment. Every single prototype has a specific reason.

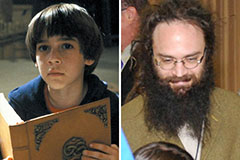

Barret Oliver Then & Now!

Barret Oliver Then & Now! Sam Woods Then & Now!

Sam Woods Then & Now! Matilda Ledger Then & Now!

Matilda Ledger Then & Now! Nancy McKeon Then & Now!

Nancy McKeon Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now!